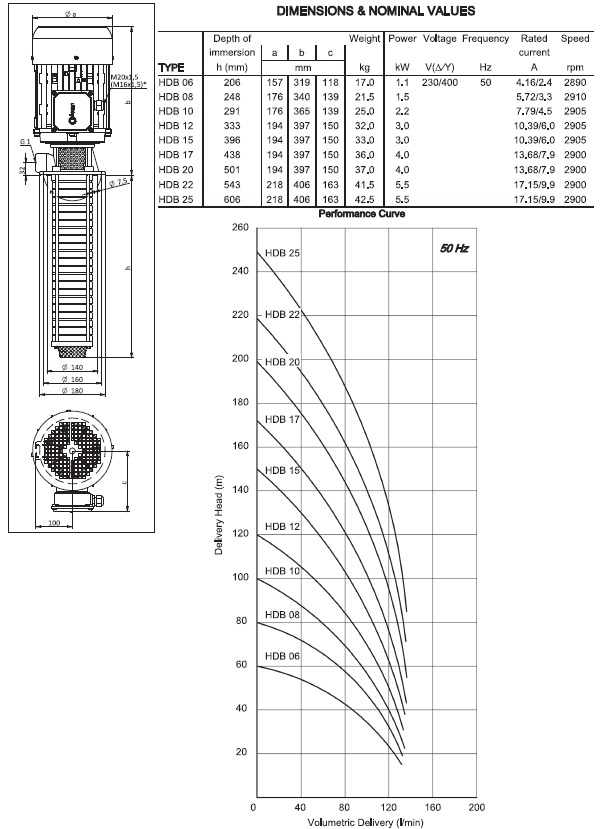

HDB Pump - H Series - Pumps

Application Areas:

- Machine Tools: The HDB Pump is used to pump cooling and lubrication fluids, extending tool life and ensuring more precise and smoother machining.

- Deep Hole Drilling: With pressures up to 25 bar, the HDB Pump is an ideal solution for deep hole drilling operations. Its high-pressure capacity ensures the desired depth and smooth surface quality in the drilled hole.

- Circulation Systems: The HDB Pump ensures continuous fluid circulation in systems, enabling more effective heat transfer and cooling processes.

- Cutting-Cooling Fluid Pumping: The HDB Pump is ideal for pumping cutting-cooling fluids, making cutting operations cooler and more efficient.

Pumped Fluids:

The HDB Pump can pump a wide range of fluids:

- Cooling fluids

- Cutting oils

- Grinding oils

- Water

Fluid Properties:

- Fluid temperature should be between 0°C and 80°C.

- Kinematic viscosity should be between 1 and 30 mm²/s.

Pump Materials:

The HDB Pump is made of high-quality materials for long-lasting and durable operation:

- Pump body: Cast iron - DIN GG 25

- Lower part: Sheet metal

- Diffuser: Stainless steel - DIN 4301 (AISI 304)

- Impeller: Stainless steel - DIN 4301 (AISI 304)

- Filter: Stainless steel - DIN 4301 (AISI 304)

- Pump shaft: Stainless steel - DIN 4401 (AISI 316)

- O-ring: Viton

- Mechanical seal: C - SiC - Viton (Optional: TC - TC - Viton)

Electric Motor:

The HDB Pump operates with 3-phase asynchronous motors and has an IP 55 protection rating. It is highly durable for challenging working conditions, with a 2-pole motor option available.

Other Features of the HDB Pump:

- Easy installation and maintenance

- Wide performance range

- Durable and robust structure

- Pressure up to 25 bar

- Quiet operation